Comprehensive Guide to Corrugated Plate Interceptor

Introduction

Now when we have envisaged about the wastewater and it is various technologies applied for the reconcentration of oil then Corrugated Plate Interceptor (CPI) can be known as more efficient. This innovative system is widely used in different fields to deal with the treatment of oily wastewater. Corrugated Plate Interceptor thus employs the principles of different gravities or densities thus useful in environmental analysis and sustainable water treatment processes.

What is a Corrugated Plate Interceptor?

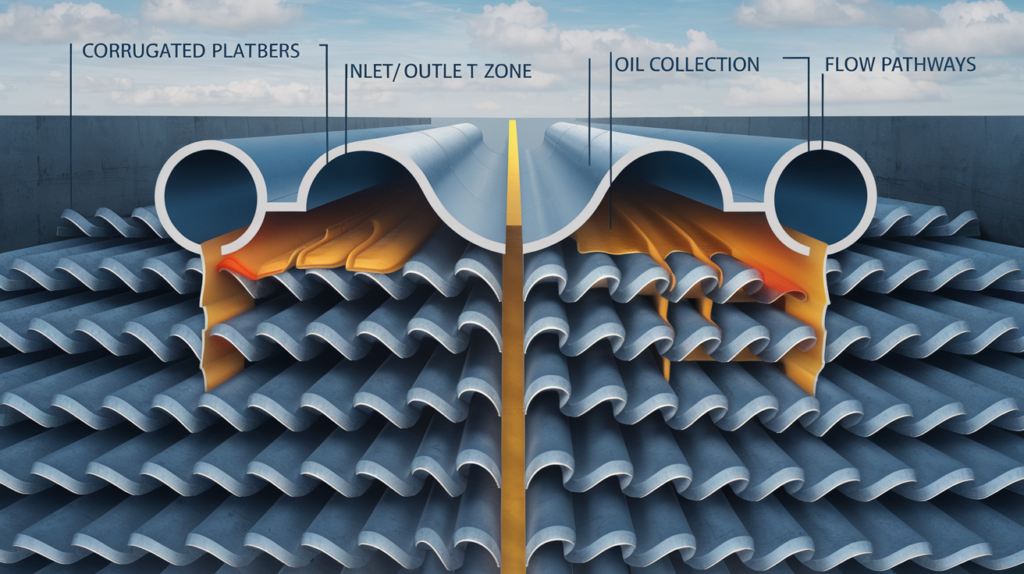

A Corrugated Plate Interceptor is a mechanical unit designed for removal of oil and solid materials from water in wastewater treatment process. It is made of a sequence of the inclined, corrugated plates designed to provide a vast area of interfacial contact between the oil and water. The corrugated structure helps achieve better adhesion of oil droplets to move them up to the surface while other materials sink to the base of the container.

Key Components of a Corrugated Plate Interceptor (CPI)

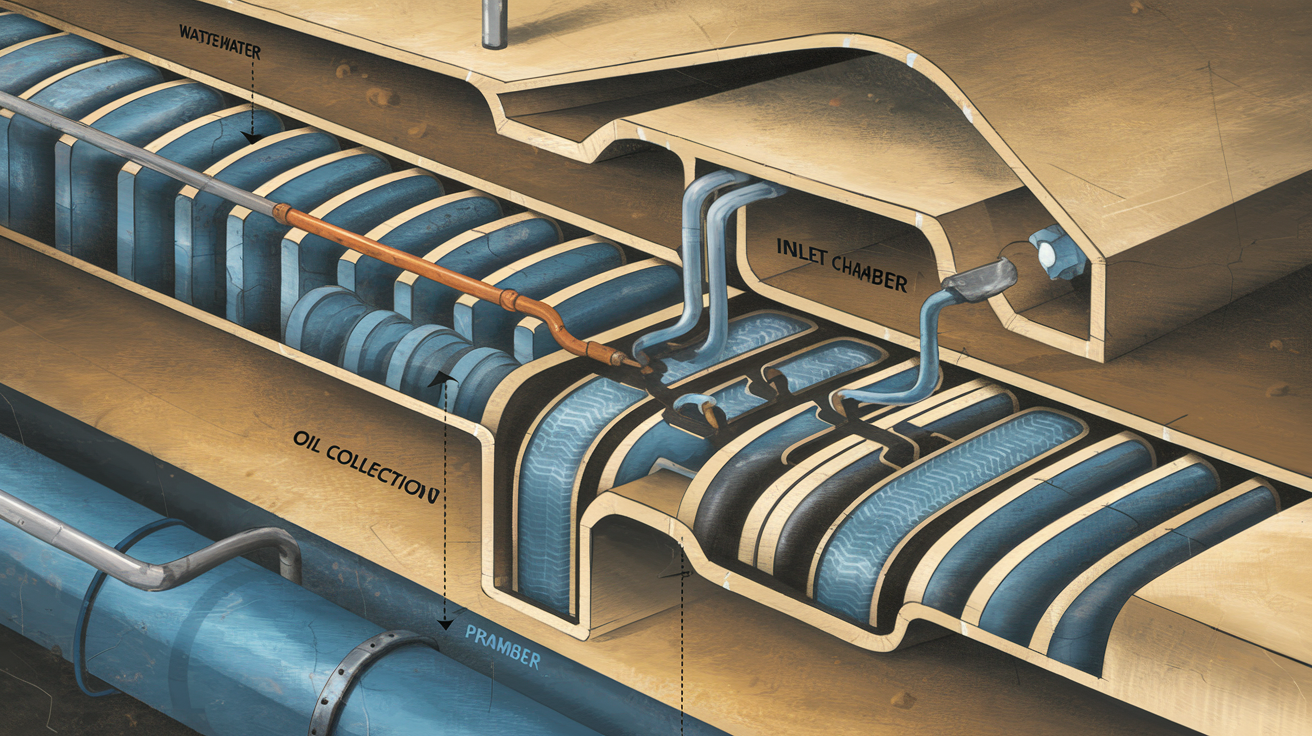

- Inlet Chamber: This is where the incoming wastewaters come in the treatment plant at the start of the CPI. The design will also help in the uniform distribution over the pate pack.

- Corrugated Plates: More specifically, these plates are at a certain degree to form some passage ways for the wastewater to pass through and at the same time let the oil to settle.

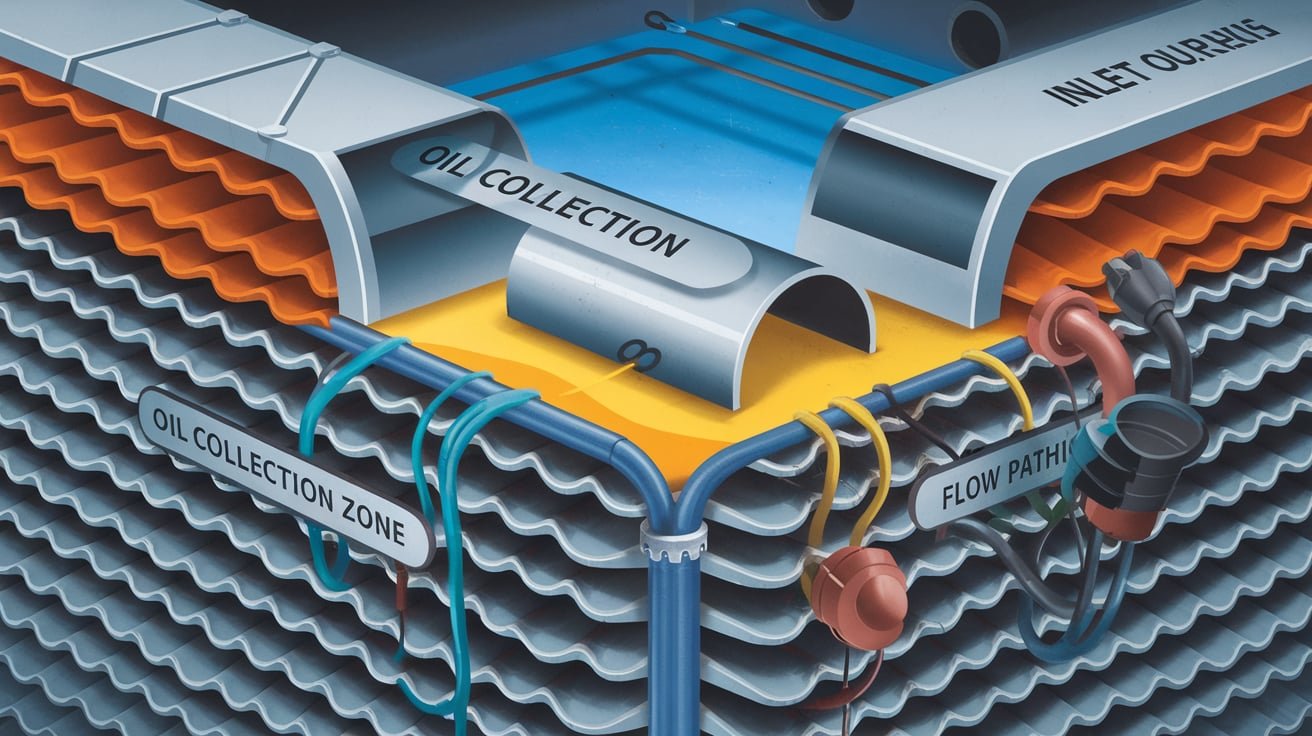

- Oil Collection Zone: When oil rises, it tends to concentrate in this part of the reservoir so it can then be collected and retrieved.

- Outlet Chamber: Water treated passes through the plates leaves this chamber, User full name: Alvin Mangarero-Water Resource Faculty/Department: Environmental Health Programme.

How Does a Corrugated Plate Interceptor Work?

The working principle of a Corrugated Plate Interceptor is rooted in the principles of physics, which gives the technology advantages for oily wastewater treatment.

Step-by-Step Process

- Flow Distribution: Sewage plays a critical role in the CPI through an inlet chamber that helps provide an even flow of water across the plates’ corrugated structure.

- Separation Mechanism: The inclined plates allow the wastewater to flow through them, and due to the lower density the lighter oil droplets float up. At the same time, large particles, more commonly referred to as solids, remain on the bottom part of the interceptor.

- Coalescence of Oil Droplets: The geometry of corrugated plates helps promote coalescence of smaller oil droplets into the larger one that should enable it float to the surface.

- Collection of Separated Oil: The excessive oil is produced at a regulative weirage, which enables operators to control and discharge the substances effectively.

- Discharge of Treated Water: Disinfectant water discharges from an outlet chamber out to be further treated or discharged in receiving waters.

Factors Influencing Performance

Several factors can influence the performance of a CPI:

- Flow Rate: Higher flow rates may influence residence time and may result to low separation efficiency.

- Oil Characteristics: The nature of the oil present and its viscosity will often determine just how well it is possible to separate it from water.

- Temperature: As for the impact of separation dynamics, changes in temperature can influence both, density and viscosity of used fluids.

Applications of Corrugated Plate Interceptors

CPIs are flexible systems working in different sectors mainly because of their efficiency in the treatment of oily water.

1. Industrial Wastewater Treatment

CPIs play important roles in industrial applications where they extract oil and grease from wastewaters produced by production lines. Manufacturing industries including the automotive, metal fabrication and foods usually apply CPIs for compliance in environmental standards.

2. Stormwater Management

The various CPIs act as critical innsomuch that they dare manage the stormwater runoff which may contain the hydrocarbons and other inflammable beings found in the urban areas industrial sites. Because stormwater is often heavily contaminated, removing and treating it before it discharges into the aquatic environment is crucial so that CPIs assist in preserving water life.

3. Chemical Processing

The chemical producers emit oily wastewaters with solvents in some instances. CPIs are conducted to filter out these pollutants prior to discharge or by passing through other treatments to achieve required limits of discharge standards.

4. Oil & Gas Industry

CPIs are utilized in the oil and gas production process where produced water is water that has interacted with hydrocarbons during the extraction procedures then discharged or recycled.

Advantages of Corrugated Plate Interceptor

As appealing as it may be, the use of CPIs has some advantages that make it easier to favour the treatment of oily wastewater.

High Efficiency

CPIs offer higher separation efficiency than traditionally used separators because of the device design emphasising enhanced surface area and subsequently, the efficiency of oil droplet coalescing.

Space-Saving Design

It will be noted that CPIs is compact-sized making it possible to install them in constrained places. They are vertically oriented, which results in their occupying less floor area than traditional separators.

Low Maintenance Costs

After installation, the CPIs’ level of maintenance is very low as compared to the other treatment systems. Typically, scrapers and plate soundness checks are sufficient to continue performance tests when modified and used regularly.

Robust Performance

CPIs can be used in flow rate changes since they can withstand changes in temperature and chemical composition hence can be used in so many applications.

Disadvantages of Corrugated Plate Interceptor

However, other than the benefits mentioned above, there are some limitations of CPIs which the user need to consider.

Higher Effluent Oil Concentration

While using CPIs, oil is efficiently removed from water; nonetheless, the treated effluent might contain a relatively higher concentration of residual oil than what is obtained using other improved effluent treatment processes such as membrane filtration or even some chemical treatment processes.

Dead Zones

Sometimes it is possible to have high flow velocities in the interceptor, which are undesirable in that they promote the formation of dead zones, where flow velocities are low and which may also reduce the effective surface area for separation.

Maintenance of Scrapers

Indeed, the scrapers, which are essential in removing settled solids, are expensive, and, in addition, call for periodic servicing to guarantee their proper working.

CPI Selection Criteria: Basic/Key Factors

Choosing the right CPI for your application involves several critical factors:

Flow Rate Requirements

Estimate individual flow rate requirements according to the generation rates of wastewater in the operations. Check that the selected CPI could perform under these circumstances without a reduction of performance.

Type of Contaminants

Determine which type of analysis the CPI is appropriate for the types of oils or solids I am removing from the wastewater stream. Some designs may be more appropriate when it comes to one or the other type of pollutant.

Installation Space

It is also important for a CPI model to take into consideration available installations when choosing between the models. A small cabinet design gives versatility in the positioning of the equipment but precise considerations have to be made concerning servicing.

Regulatory Compliance

Check for compliance of the CPI you decide to employ with local environmental standards in the matter of effluent quality and discharge standards. It is prerequisite to steer clear of penalties and retain operating permits Compliance involves adhering to.

Corrugated plate interceptors’ maintenance best practices.

To ensure optimal performance and longevity of your CPI system, follow these maintenance best practices:

Regular Inspections

The overall performance should be monitored regularly to look for signs of wear and or damage on plates and scrapers, occasionally. This can be checked early enough to avoid incurring a fortune in future.

Cleaning Protocols

Develop cleaning requirements according to conditions of operation. Empty bottom chamber and wash any kind of deposit from the oil foam zones at certain intervals.

Monitoring Performance Metrics

Record metrics of influent and effluent oil concentra on and flow rates in the system. It makes it easier to confront various problems in advance if these key performance indicators are observed.

Training Personnel

All staff in the relevant departments that are assigned the task of operating and maintaining the CPIs should undergo training on matter relating to system operation and maintenance. Qualified manpower is a key factor to improving the reliability of a given system.

Conclusion

The Corrugated Plate Interceptor is a useful piece of equipment in the development and management of present day wastewater treatment plants especially for organizations with oily wastage. Due in particular to its design it can operate effectively for separation and while requiring low space and minimal spare parts means low maintenance costs. Therefore, the knowledge of how CPIs operate, their uses, strengths and weaknesses, selection factors will aid organizational decisions related to the usage of CPIs.

With more industries moving towards sustainable production and conforming to environmental guidelines investing in good wastewater treatment solutions such as CPIs will go a long way in conserving the environment.

FAQs

In general, what does a Corrugated Plate Interceptor serve to do?

The basic purpose of a CPI is to provide separation between oil and water in oily wastewaters by gravity-based operations on inclined corrugate plates.

How does a CPI attain an efficient separation?

Corrugated Plate Interceptor also employs inclined corrugated plates that allow the formation of laminar flow zones necessary to buoyant oil droplets while simultaneously settling denser phase materials at the bottom.

What are the limitations of CPIs?

Yes, limitation include may contain higher residual oil concentrations from treated effluent compared to other methods and maintenance issues with respect to solid removal by means of scrapers.

In which applications can Corrugated Plate Interceptor be installed?

CPIs can be applied in industrial wastewater treatment, Storm water facilities, Chemical processing industries or specific to oil and gas industries.

What does it take in terms of associated costs to maintain CPIs?

Despite the fact that CPIs need little maintenance, there is a need to inspect scrapers and checkplates, as well as to implement standardized cleaning procedures according to working circumstances.